Supplier: Synergy Manufacturing Works (Suzhou) Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 83

Complex aluminum alloy parts precision CNC machining for machinery parts

Telecommunication

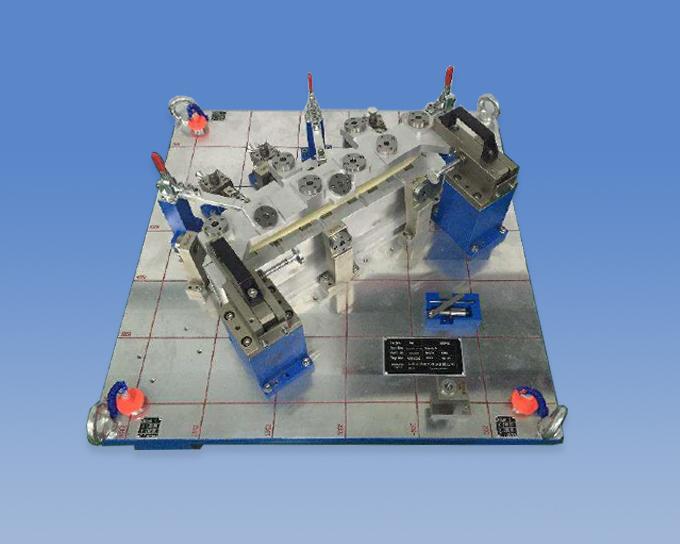

Supplier: Jianshengya Precision Mold Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 82

Customized Fixture

Tooling&Fixture

Automation

Supplier: Suzhou Hongyuda Pml Precision Mechanism Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 70

Machined Plastic model rapid prototyping

Plastic Mold

Automation

Supplier: Suzhou Hongyuda Pml Precision Mechanism Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 70

Stamping part Prototype part for Gaming PC Cases

Automation

Supplier: Synergy Manufacturing Works (Suzhou) Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 83

High Precision Complex CNC Machining Aluminum Parts & Assembly

Telecommunication

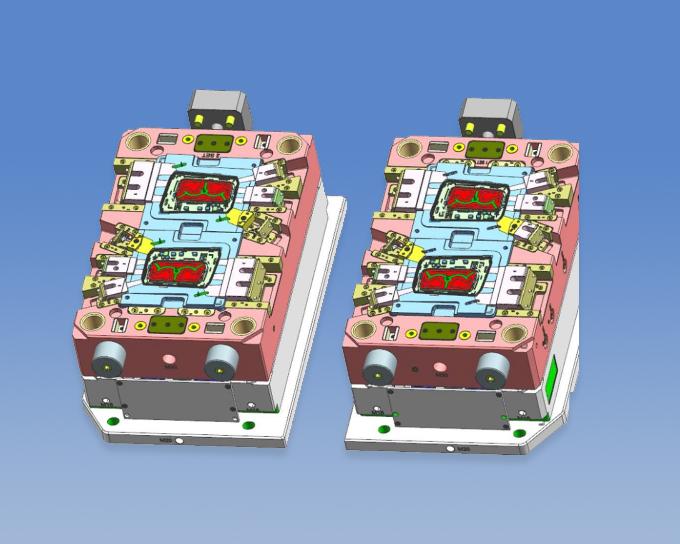

Supplier: Jianshengya Precision Mold Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 82

Plastic mold Injection Mold Making Supplier in China

Plastic Mold

Automation

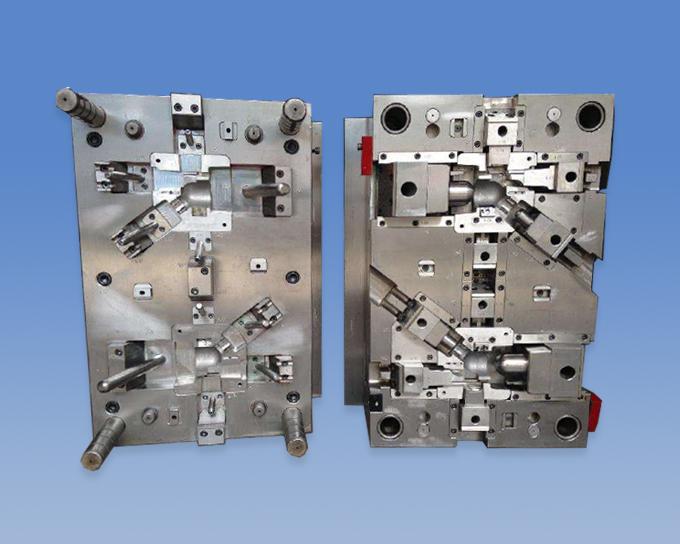

Supplier: Jianshengya Precision Mold Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 82

Injection molding design quality control

Stamping Mold

Automation

Supplier: Synergy Manufacturing Works (Suzhou) Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 83

Machining parts for Communications industry

Telecommunication

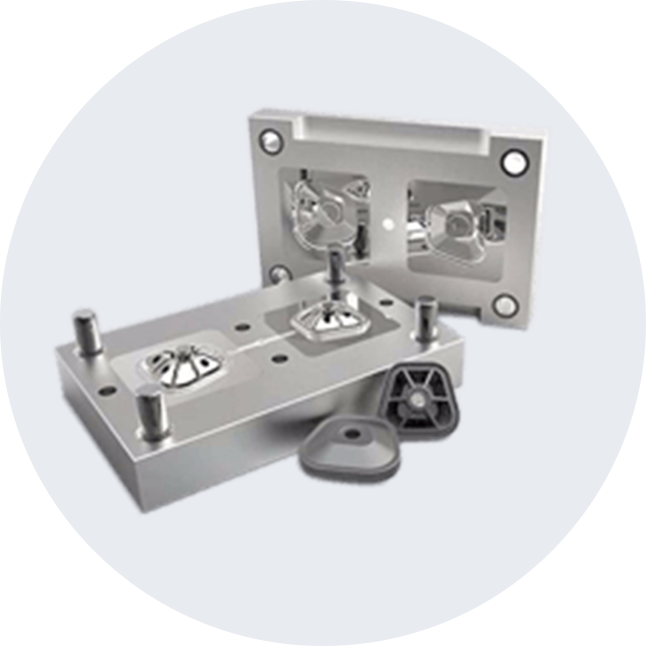

Supplier: Jianshengya Precision Mold Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 82

Plastic mold for Car Logo

Plastic Mold

Automation

Supplier: Synergy Manufacturing Works (Suzhou) Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 83

Precision aluminum copper auto spare parts by complex CNC machining

Automotive

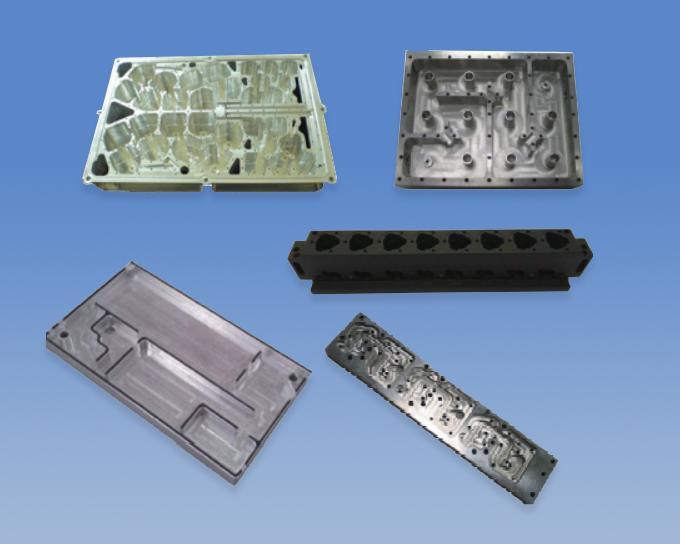

Supplier: Jianshengya Precision Mold Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 82

Plastic Mold Design, injection mold

Plastic Mold

Automation

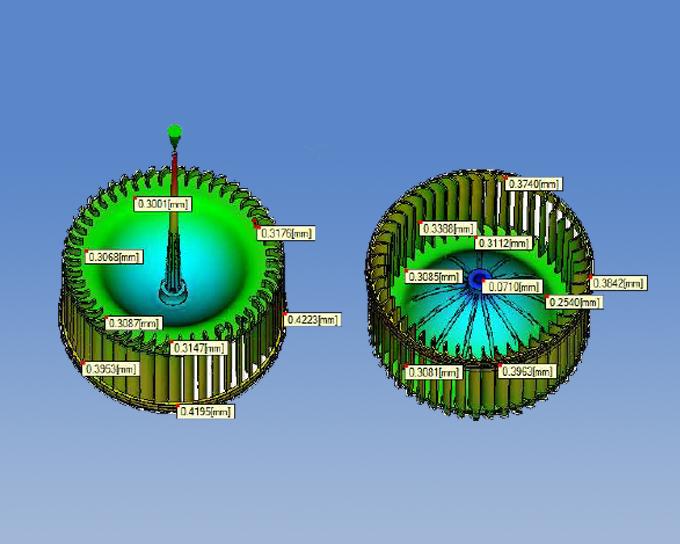

Supplier: Jianshengya Precision Mold Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 82

Plastic mold flow analysis

Plastic Mold

Medical Equipment

Supplier: Suzhou Hongyuda Pml Precision Mechanism Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 70

Machined plastic automotive part prototyping

Automation

Supplier: Suzhou Hongyuda Pml Precision Mechanism Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 70

Machined plastic bus model

Plastic Mold

Automation

Supplier: Suzhou Hongyuda Pml Precision Mechanism Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 70

Machined plastic part

Automation

Engineers, engaged in product design, know that every design of a new product needs to confirm the structure and appearance of the product or do some testing (e.g. temperature testing, drop testing, collision testing, structural assembly and so on). Once test passes and gets approval from the end user, molding production for mass production could be arranged. So rapid prototyping is crucial. In China, rapid prototyping is also known as the first sample. There are several ways to make prototype:

1. CNC machining

CNC machining is an ideal method to make high-quality rapid prototypes from plastic or metal without investing expensive tooling. Its process includes turning, milling, drilling, tapping, boring, and grinding for a variety of materials.

CNC machining for prototype is based on new 3D drawing. Most CNC equipment is 3-axis to 5-axis machine and some complex structures need to be split and processed first, then assembled together. Most materials, plastic and metal, can be used in CNC machining for quick prototyping, such as ABS, PC, PMMA, POM, PP, PA66, PPS, fire-resistant ABS, ABS-PC, PC-GF, aluminum alloy, brass, stainless steel, iron and so on. CNC machining prototyping is suitable for high material strength products, big size products and high precision products.

CNC machined prototype achieves tighter tolerance with better surface finishes than by other prototyping methods. And it also achieves all features needed for a fully functional part, including tapped, threaded holes and precise flat surfaces.

2. 3D printing

Now a day, more and more design engineers prefer to use 3D printing for first sample because cost of 3D printing is much lower than before and processing speed is fast compared with other processing modes. And 3D printing could help make very complex product structure. Efficiently make one off parts and create highly complex geometries that are only possible with 3D printing. The SLA laser 3D printing is most commonly applied to high precision, smooth surface and large printable size product. The printed material is similar to ABS. New samples with 3D printing can be colored, electroplating and so on.

3. silicone compound molding

Silicone compound molding use silicone materials to make molds. And this mold is used to copy products. Firstly, make a very first mother board, put the board into the silicone liquid, wait for silicone liquid curing to cut out the board, then a silicone mold is done. Vacuum condition is needed if using silicone for mold injection, otherwise the product will have pores and cannot be used. Silicone compound mold is suitable for small-volume products, such as medical equipment. Many of the medical devices you see in the hospital are made by silicone compound. Silicone compound molds can be manufactured by ABS, PC, PP, soft glue, PMMA, nylon, PVC and etc. However, dimensional accuracy of product made by silicone compound molding is not high because mold tolerance is within the range of 0.1-0.2mm.

4. mud carving

Mud carving is based on the shape of product with mud fabricated molding. Mud carving doesn’t need 3D files, a sketch hand drawing is enough for prototyping. While the cost of mud carving is high because mud carving needs experienced master craftsman. The prototyping time is longer since it requires several rounds confirmation and modification. Mud carving is suitable for the toy samples and doll model samples.

As industrial software becomes even more sophisticated, many 3D drawing software can accurately reflect the designer's thinking. There are some young designers who believe that it should be no problem to build mold based on 3D drawings but some problems still appear: like size problems, structural interference, market demand changes, some functional tests fail and so on.

Prototyping starts before molding. To make a set or several sets of products first to confirm the structure, size, appearance and etc., correct, confirm the corrective action and then make mold. The advantage of prototyping is as follows:

● Verify design and improve: rapid prototyping before mass production enables you adjust and improve product timely so as to gain satisfied ones.

● Shorten development time: a lot of work needs to be done before new products goes to the market: like market research, financing or funding, as well as production activities in order to make success for new products. Since molding is expensive, there is a risk to invest mold at the very beginning. The prototyping is produced to support market research or financing so that the project could goes smoothly.