Supplier: Changsu Xunda Powder Metal Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 91

Powder Metallurgy Companies Sintered Automotive Part-SS

Fe based

Automotive

Supplier: Changsu Xunda Powder Metal Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 91

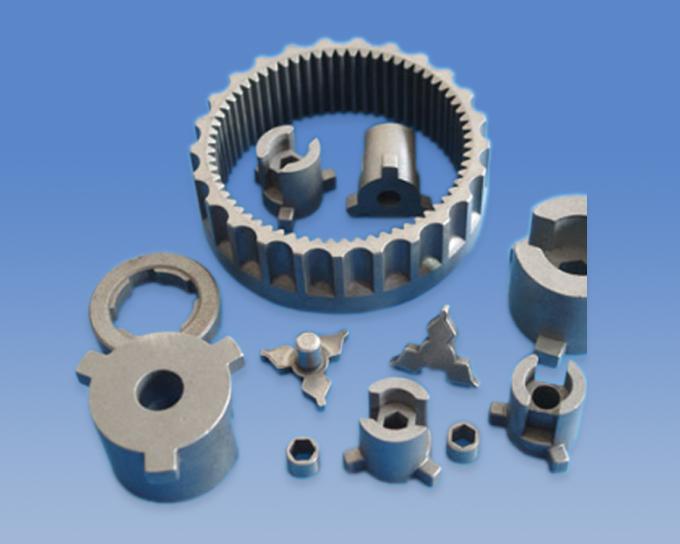

Powder Metallurgy Manufacturers Gear Part For Electric Power Tool

Fe based

Automotive

Supplier: We-Transcend Suzhou Precision Powder Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 80

Powder Metallurgy Suppliers - Angle Grinder

Fe based

Power tool

Supplier: Suzhou Silver Alloy Co.,Ltd.

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 83

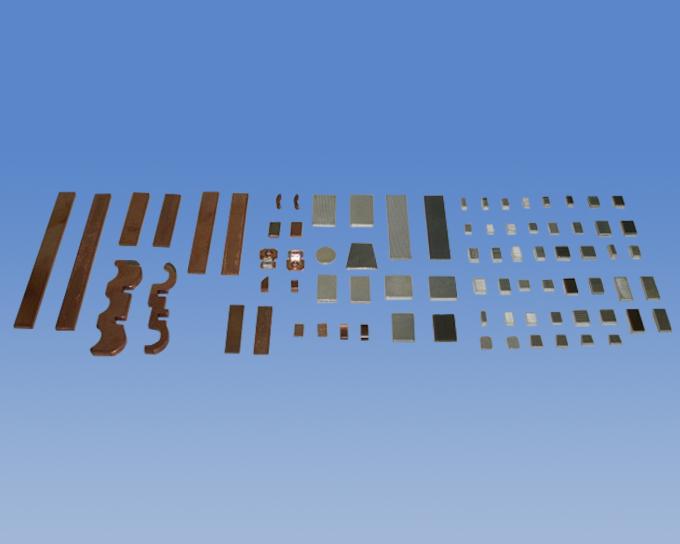

Powdered Metal Parts Manufacturer -Silver Tungsten(CuW) Tips

Copper

Automation

Supplier: Suzhou Laikes Powder Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 75

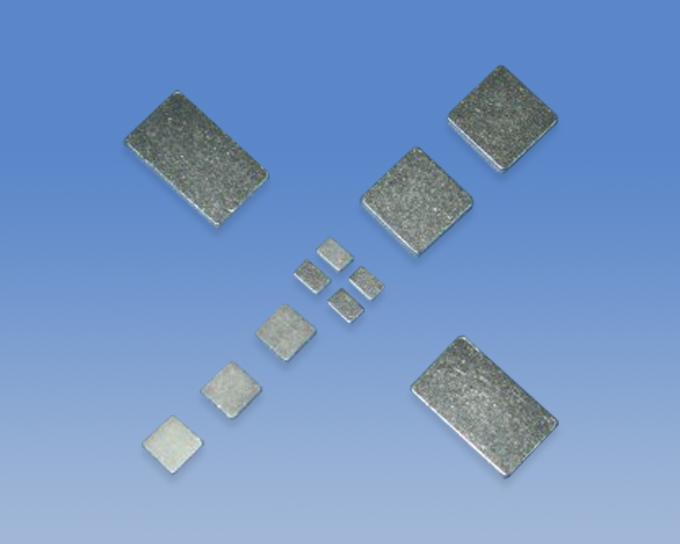

Precision Powder Metallurgy Components Company

Stainless steel

Automotive

Supplier: Suzhou Laikes Powder Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 75

Metal Injection Molding (MIM) Supplier - Stainless Steel

Fe based

Telecommunication

Supplier: We-Transcend Suzhou Precision Powder Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 80

PM Manufacturer PM Components For Power tool Spacers Bushings Lock rings Throttle Valves

Fe based

Power tool

Supplier: Suzhou Silver Alloy Co.,Ltd.

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 83

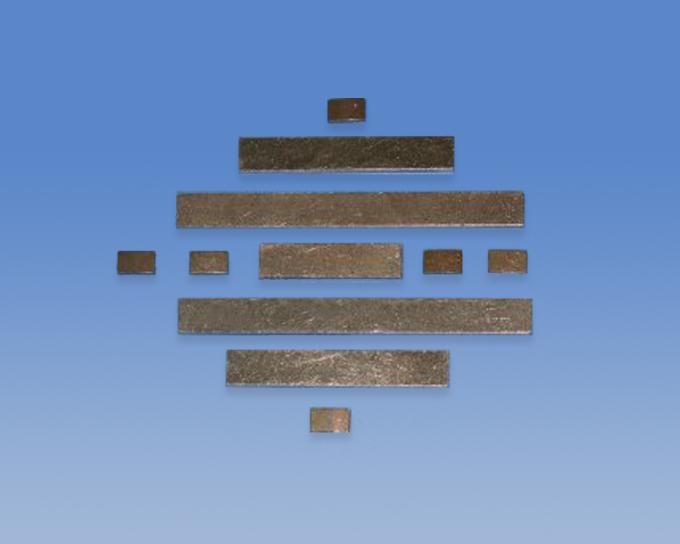

Powder Metallurgy Supplier - Silver Alloy Metallurgy Parts

Ag

Electricity

Supplier: Suzhou Silver Alloy Co.,Ltd.

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 83

Powder Metallurgy Supplier China -Silver Graphite(AgC) Contact Tips

Ag

Electricity

Supplier: Suzhou Laikes Powder Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 75

Precision Powdered Metals Supplier

Fe based

Telecommunication

Supplier: We-Transcend Suzhou Precision Powder Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 80

Sintered Metal Components Manufacturer- Tension Components

Fe based

Automotive

Supplier: Suzhou Laikes Powder Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 75

Metal Injection Molding MIM Supplier, Custom MIM Parts

Fe based

Telecommunication

Supplier: We-Transcend Suzhou Precision Powder Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 80

Powder Metal Component Manufacturer PM Parts Pawls, Indentor Holders, Socket

Fe based

Power tool

Supplier: Suzhou Silver Alloy Co.,Ltd.

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 83

Powder Metallurgy Manufacturer - AgNi Contact Tip Extrusion

Ag

Electricity

Supplier: Suzhou Laikes Powder Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 75

MIM Supplier Metal Injection Molding -Steel

Stainless steel

Automotive

What is powder metallurgy?

Powder metallurgy (PM) is a process of forming metal parts by heating compacted metal powders to just below their melting points temperature.

In other words, PM is a metal shaping process that creates near-net parts from powdered metal.Such feature makes this process ideal for mass production.The process mainly involves four basic steps.

- Powder Preparation: carefully weigh powdered metals or alloys to produce uniform distribution of the particles. Powders can be pure metals, non-metallic, metal compounds and other compounds.Typical metal powders include bronze, brass, nickel, silver, iron-nickel and various grades of stainless RM.The required raw material, metal powder, can be self-mixing or pre-mix powder provided by powder suppliers.

- Mixing and Blending: The mixture may include specified quantities of die lubricants, graphite and other additives.

- Compacting: Predetermined amounts of blended powder is fed into die cavities and compacted into the desired shape, size and density.

- Sintering: Sintering takes place in a continuous belt-driven controlled atmosphere furnace at a temperature below the melting point of the primary metal constituent used. The sintering process bonds the powder particles together metallurgically by atomic transfer.

What are the benefits of Powder Metallurgy?

Powder metallurgy parts is close to final size of the product and the material utilization rate is more than 97%.The PM process is capable of producing several hundreds to several thousands parts with close dimensional tolerances per hour. It is particularly suitable for a wide range of applications in the automotive and home appliances industries, which manufacturing small size but complex structure components.

The advantages of such technology enables up and coming low-cost bushings, bearings and structural parts.

Generally speaking, complex parts requires irregular curve, eccentric, radial projection, or recess, thus it could be produced by powder metallurgy technology only. Parts that requires irregular hole, keyway, flat side, or square hole that are not easily machined can be made by powder metallurgy.

PM provides for controlled permeability and allows for the use of inventive composites with unique properties. There is great versatility with a wide latitude of part shape and design along with extensive material flexibility.

To summarize, the PM process provides close dimensional tolerance, minimal machining, good surface finish, and excellent part-to-part reproducibility from moderate to high volume part production.

Advantages of Powder Metallurgy :

1. The parts can be produced clean, bright and is ready for use.

2. The composition of the product can be controlled effectively.

3. Articles of any intricate shape can be manufactured.

4. Close dimensional tolerance can be achieved.

5. The machining operation is almost eliminated.

6. Parts have excellent finish and high dimensional accuracy.

7. High material utilization.

8. Metals and non-metals can be mixed in any proportion.

9. A wide range of properties, such as porosity, density and etc. can be achieved effectively.

10. High production rate

11. Reduce production time.

12. No highly skilled labor requirement.

13. Composition structure and properties can be controlled easily.

14. A wide range of parts with special electrical and magnetic properties can be produced.