Supplier: Shanghai Yanjing Precision Structural Parts Co.,Ltd

Location: Shanghai

Supplier Rating by PINTUU: 82

OA drive shaft pin

Stainless steel

OA

Supplier: Suzhou Heli Machinery Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 81

CNC Machining plastic base part-insulating material-0.1kg

Thermoplastic

Automation

Supplier: Suzhou Sweat Intelligent Technology Co., Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 81

CNC machining part

Ferrous Metals

Automation

Supplier: Shanghai Yanjing Precision Structural Parts Co.,Ltd

Location: Shanghai

Supplier Rating by PINTUU: 82

Eelectric equipment Axle rod SS 6g

Stainless steel

Tooling

Supplier: Suzhou Speedup Electron Science&Technology Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 78

Galvanized Spraying Gun Head

Ferrous Metals

Telecommunication

Supplier: Shanghai Libang Medical Equipment Co., Ltd

Location: Shanghai

Supplier Rating by PINTUU: 85

Machined bending bracket for Wheel chair painting

Medical Equipment

Supplier: Changzhou Qiaote Machinery Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 81

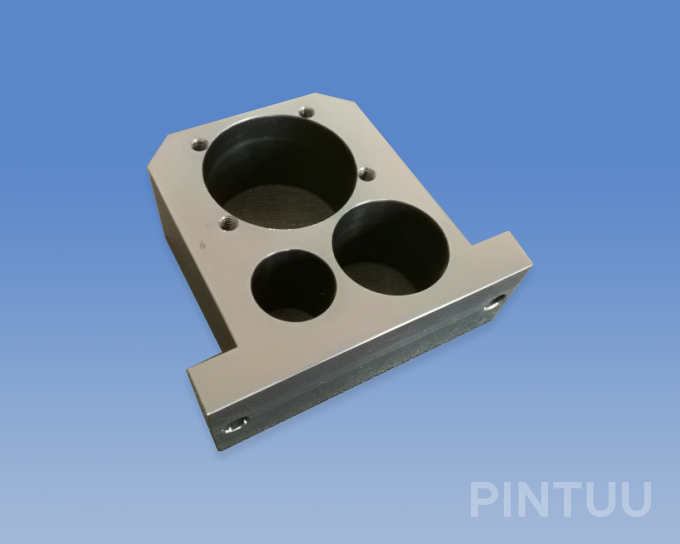

Machined fittings aluminum -22.2g

Aluminium

Automotive

Supplier: Suzhou Heli Machinery Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 81

Machining pulley for block and tackle-Zinc plated iron-1kg

Ferrous Metals

Automation

Supplier: Suzhou Shuanghua Technology Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 72

Non standard mechanism close shaft

Ferrous Metals

Tooling

Supplier: Suzhou KSC Precise Machinery Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 88

Medical analysis equipment milling component-#45-Medical device

Stainless steel

Medical Equipment

Supplier: Suzhou Elite Machinery Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 90

Mounting plate with white painting-steel casting-5.5Kg

Ferrous Metals

Medical Equipment

Supplier: Suzhou Speedup Electron Science&Technology Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 78

Optical module housing gold plating

Stainless steel

Telecommunication

Supplier: Wuxi Xinlucky machinery Co.,Ltd

Location: Wuxi,Jiangsu

Supplier Rating by PINTUU: 82

Pipe for flow control 20# 174g

Ferrous Metals

Fluid Management

Supplier: Shaoxing Shangyu Hengfeng Manufacturing Co.,Ltd

Location: Shangyu,Zhejiang

Supplier Rating by PINTUU: 82

Pipe interface-seamless pipe-1kg

Stainless steel

Automation

Supplier: Shanghai Yanjing Precision Structural Parts Co.,Ltd

Location: Shanghai

Supplier Rating by PINTUU: 82

Printer thread rod SS 12g

Stainless steel

OA

Since CNC technology was developed in the 1970s, CNC machines have been used to milling, turning, boring, grinding, tapping and cutting. The primary advantage of CNC machining is that it allows for greatly improved accuracy, efficiency, productivity and safety over other forms of metalworking equipment. With CNC machining equipment, the operator is placed less at risk and human interaction is significantly decreased. In many applications, CNC can continue to operate unmanned over the weekend. If an error or a problem occurs, the CNC software automatically stops the machine and notifies the off-site operator. A CNC is considered an expensive investment for manufacturers. There are broad ranges of CNC machinery. Lathes, mills, drills, laser cutting, laser engraving, water cutting, plasma cutting, and many other machining tools can be automated.

In past 20 years, China's CNC machining manufacturing industry is developing rapidly. In Jiangsu and Zhejiang province, there are many CNC manufacturers have ISO standard management, advanced equipment, high quality control processing, most are produce in auto parts, precision electronic components, and medical parts. They are good in plant hardware environment and corporate culture construction. From our point of view, their hardware is not even worse than the first-class manufacturing companies we have seen in Germany. Of course, there is still a lot of low-end CNC machining suppliers in China, they still in red-sea competition.

Machining towards high-precision direction, processing accuracy is still continuously improving, high efficiency high precision and lower cost always the theme for development. The efficiency of processing and the stability of processing are directly related to the precision machining equipment.

Outsourcing will become more common, especially at the high end of the market. OEMs and Tier 1 suppliers are constantly outsourcing precision machining to precision machining suppliers to optimize management, save costs and avoid large investment of equipment and high-tech barriers. In this trend, independent precision machining suppliers are expected to gain more market share.

Some of our audited suppliers:

Suzhou Heli machining:

The supplier that is more than 25 years experience for precision parts machining. Sales revenue is about CNY 45M in year 2018.

There are around 120 employees, 3 key technicians with more than 15 years working experience.Welding process is installed, thus they tend to more assembly business.

Most their customers are in medical industry, they prefer highmix and low volume order. Sales focus on local foreign invested company. Key customer is HITACHI 40%, GETINGE 10%,Outotec 15%.

one staff take English translation

The company certified ISO13485, Product quality performed 100% check which results in good ppm level and better customer's satisfaction. 8D tool is used. The maintenance performs regularly.

Lean will be performed in year 2019

Jin Shi Bo machining and assembly:

This company might be the best machining factory we ever visited, and the boss is also very confident about this view and really pround of his company. First impression for this company is like a nice Westen company, clean and well organized.

The company is a new&high-tech company. It was founded in year 1999. Total 266 employees generated $16M sales in year 2018. Main process includes machining, welding, assembly. They own advanced equipment include four axis and five axis of CNC and good production process control.

They focus on precision instrument industry, food industry, Automotive industry and Medical device industry. The company prefers high-mix order. Boss has technical background in machining for more than 20 years. The company has 23 engineers with rich experience.English ability is available. ISO 9001 certification.

Incoming inspection, FA, process and final inspection are performed to control product quality. And it resulted in very low PPM from customer side. Workshop are organized well, Lean and CIP culture in company development.

Findings: production capacity almost fully utilized (>85%).