Supplier: Suzhou Shareway Precision Manufacturing Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 81

Aluminum sheet Custom Metal Stamping blue powder coating

SPCC

Agriculture and forestry

Supplier: Suzhou Mecho Mechanical Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 83

Automobile impeller stamping part

Steel

Automotive

Supplier: Suzhou Weiye Metal Products Co., Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 85

Lawn mower pan 21 deep drawn stamping part

SPCC

Garden Equipment

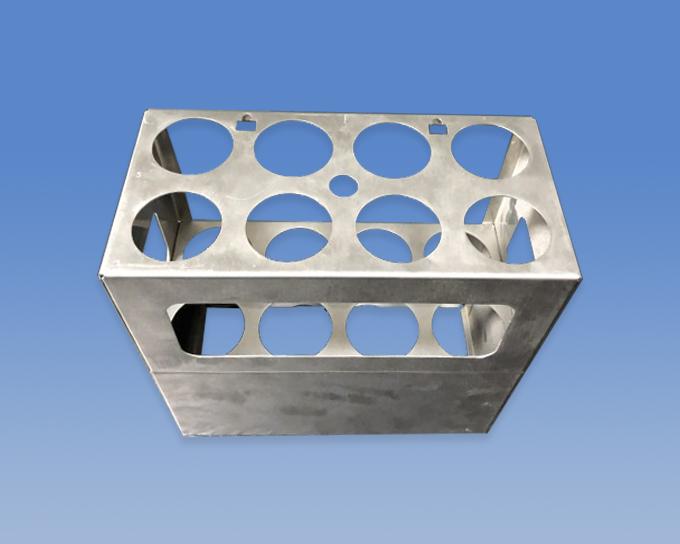

Supplier: Suzhou Elite Machinery Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 90

Welding base part-CS-4.2Kg

Steel

Medical Equipment

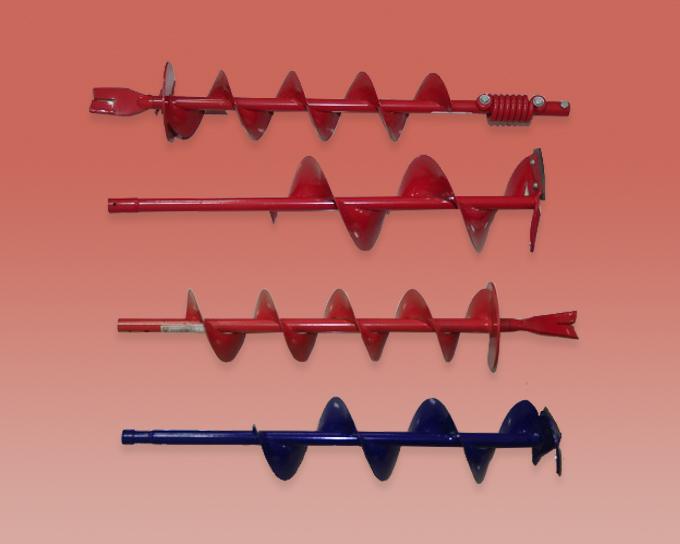

Supplier: Suzhou Mecho Mechanical Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 83

Automotive Bumper cover stamping part

Steel

Automotive

Supplier: Suzhou Weiye Metal Products Co., Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 85

Lawn mower blade stamping part

Steel

Garden Equipment

Supplier: Suzhou Shareway Precision Manufacturing Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 81

SUS304 stamping for Agricultural equipment

SPCC

Agriculture and forestry

Supplier: Suzhou Mecho Mechanical Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 83

Automobile shock absorber stamping part spring tray

SECC

Automotive

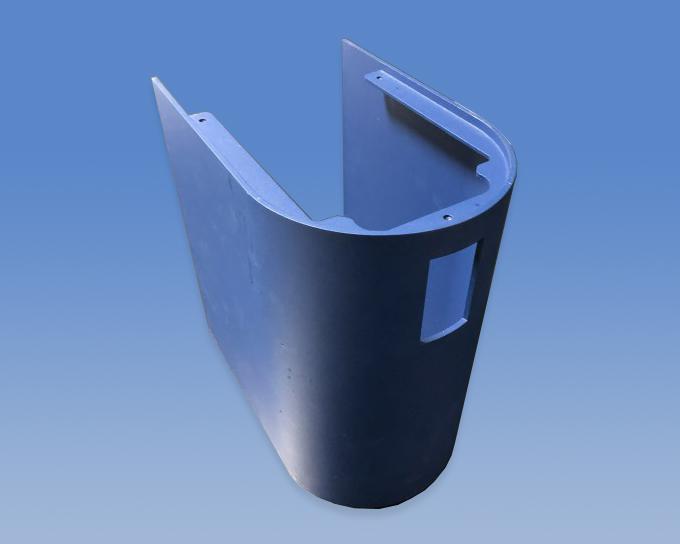

Supplier: Suzhou Weiye Metal Products Co., Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 85

Garden tool hole digger blades stamping part

SECC

Garden Equipment

Supplier: Suzhou Weiye Metal Products Co., Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 85

Lawn mower stamping part

SPCC

Garden Equipment

Supplier: Suzhou Shareway Precision Manufacturing Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 81

SUS304 stamping for Agricultural machine 2kg

SPCC

Agriculture and forestry

Supplier: Suzhou Weiye Metal Products Co., Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 85

stainless steel stamping part medical component part

SPCC 30

Medical Equipment

Supplier: Suzhou Mecho Mechanical Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 83

Car oil cylinder housing cover stamping part

Steel

Automotive

Supplier: Suzhou Mecho Mechanical Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 83

Car Spring Seat Shock Absorber Cap stamping part

Steel

Automotive

Supplier: Suzhou Shareway Precision Manufacturing Co.,Ltd

Location: Suzhou,Jiangsu

Supplier Rating by PINTUU: 81

Stamping part for agriculture equipment

SPCC

Agriculture and forestry

Metal stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined.

Metal stamping product’s application is very wide: home appliance manufacturing, automobile manufacturing, electronics and electrical industry, instrumentation industry, equipment manufacturing and many other industries. Most of the customers' needs is small or medium-sized metal parts.

The outstanding features of stamping products, especially those precision metal stampings, consist of:

Consistency of product quality: highly consistent in product quality and all same models are fully interchangeable

Fitness: All parts must be fit perfectly with a wide range of other parts, especially precision components for high-precision electromechanical equipment, which requires very demanding dimensional errors requirement.

High efficiency of production: The stamping process has much higher productivity than other metal forming processes, such as casting and forging, therefore, stamping is relatively cheaper.

For CNC machining, long processing cycle & high cost; powder metallurgy parts have poor strength and other defects; while thick material stamping can overcome the above problems and ensure smooth cut section to meet customers’ requirements. Thick material stamping technology can stamp the carbon steel with thickness less than 13mm , stainless steel and other materials.

Precision deep drawn parts technology is also a widely used technology. In deep drawn and ironing, some domestic metal stamping companies have accumulated rich experience: height to diameter ratio of 5:1, material diameter of ironing can be from 2mm to about 1.2mm, and at the same time to ensure that the internal and external diameter tolerance is under 0.05, such parts are mainly used in the engine, transmission and lithium ion battery industries.

China's stamping industry

From 2001 to 2010, China's stamping industry has growing rapidly and gradually step to stable growth stage from past few years. Competition changes from scale and quantity competition to high-quality, high-performance, multi-applications and cost-effective competition. In the past ten years, China's stamping industry has made a markable progress in the high-strength steel plate selection for automobiles, stamping equipment upgrade, stamping mold upgrade, stamping process improvement and software development. Although the informationization application in stamping industry is not long, it has significantly helped improve product quality and production efficiency.

Stamping products are not only sold to China mainland near me, but also sold to the world, UK, India, Germany, Italy, Mexico, Frances, US (Michigan, Ohio, Illinois…)

Although the domestic stamping industry has made great progress, from the whole stamping industry perspective, there are still certain problems, mainly consists of following three aspects:

1. Raw materials: about 95% sheet metal for automotive could be self satisfied, but some RM for high-strength car, like galvanized alloy plate, special aluminum plate, ultra-wide sheet (1,650mm or more), still depends on imports.

2. High-end mold: at present, domestic mold tech level is mainly low-end with limited profitability. Those large, precision, complex and long-life molds are still relying on imports. Mold design, manufacturing and materials cannot meet the needs of domestic automotive application. According to statistics, China's mold industry exports exceeds the import from 2010, the mold industry export reached 2.33 billion U.S. dollars in year 2014. However, the stamping mold’s import volume is larger than exports each year. Long-lived molds mostly rely on imports. The materials, design, production of stamping mold cannot meet the needs of domestic automotive development. And mold standardization level is still low, roughly 40% to 45%, about 70% below international levels.

3. High-end stamping equipment: servo presses, large tonnage multi-stations presses, high-grade high-voltage forming production lines, high-grade thermoforming production lines and other high-end equipment mostly rely on imports. Domestic stamping equipment significantly lags behind in accuracy, especially stability compared with similar international products, and integrated control technology also needs to be further improved.